102 Allied Parkway Sicklerville, NJ 08081

Bottle Labeling Machines

The right bottle labeler does more than ensure your finished products have a sleek, professional touch. It also integrates seamlessly with other tools and keeps your production line efficient and your maintenance costs under control. In addition to standard requirements like high precision, speed, and throughput, your specific types of labels and bottles will require a specific bottle labeling machine, and Pro-Motion Industries’s seasoned experts can help you select one that fits your needs and budget.

Auto Labe, Collamat, CTM, and Herma are just some of the leading bottle labeling machine manufacturers we partner with. This means we are able to bring a wide range of industry-standard bottle labeling machinery to our clients at competitive prices, along with extensive product knowledge on features, system configurations, and maintenance. Whether you need a top-of-the-line labeler for custom-shaped craft beverages, a portable label applicator for small pharmaceutical products like vials or ampoules, or the right bottle labeling machinery for any other products, we have got you covered.

Product Categories

Showing all 8 results

-

Applications

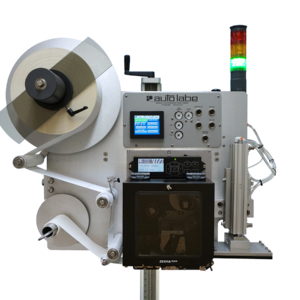

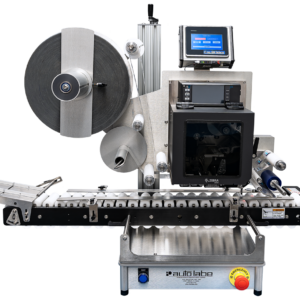

Auto Labe Model 155

Auto Labe’s new Model 155 Print & Apply system integrates a Tamp, Blow, Air-Tamp, or Smart Tamp label applicator with high performance thermal transfer and direct thermal printers. It also incorporates a color touchscreen and PLC for easy menu driven operation and control. No more relays or circuit board problems to worry about. Built to last with only the best components available for maximum versatility and performance.

-

Applications

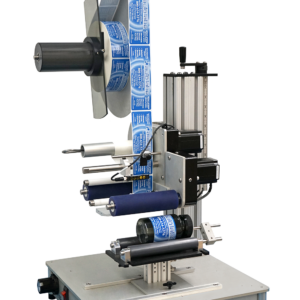

Auto Labe Model 390s

The Model 390s uses a portable tabletop approach, uniquely designed for labeling small, round products such as test tubes, ampoules, and vials.

-

Applications

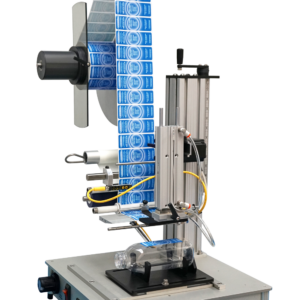

Auto Labe Model 395s

The Model 395s uses a portable tabletop approach, uniquely designed for labeling small, round products such as test tubes, ampoules, and vials.

-

Applications

Auto Labe Model 550 Semi-Automatic

The lightweight and portable Auto Labe Model 550 offers similar functionalities as a manual dispenser. It moves individual or multiple-row labels and removes them from their lining. The difference is that instead of manually pulling on the liner, a trigger on the dispenser detects the absence of a label then advances the label.

-

Applications

Auto Labe Model 550s Semi-Automatic

The lightweight and portable Auto Labe Model 550s offers similar functionalities as a manual dispenser. It moves individual or multiple-row labels and removes them from their lining. The difference is that instead of manually pulling on the liner, a trigger on the dispenser detects the absence of a label then advances the label.

-

Applications

Auto Labe Model 560s Semi-Automatic

The lightweight and portable Auto Labe Model 560s offers similar functionalities as a manual dispenser. It moves individual or multiple-row labels and removes them from their lining. The difference is that instead of manually pulling on the liner, a trigger on the dispenser detects the absence of a label then advances the label.

-

Applications

Collamat® 7300

The Collamat® 7300 is a high-performance labeler and the perfect solution for any standard application, even at high speeds or great throughput. It delivers premium, high-quality labels to products across industries, including food and beverage, pharmaceutical, storage, and logistics. With simple design and mechanical efficiency, the C7300 is easy to operate, requires minimum training and maintenance, and is an ideal investment that will yield long-term ROI.

-

Applications

CTM Labeling Systems 360a Series Label Applicator

The 360a Series Label Applicator evolved from the industry-standard 360 Series Platform. It can be configured as a merge, blow-on, or tamp-blow applicator with 5″, 7.5″, or 10″ widths. Each module can also be easily switched to the opposite hand with few or no change parts in a minimum amount of time. All units are stepper motors, built to leverage state-of-the-art electronics and an intuitive label sensor. The 360a also comes with a smart file encryption that allows for easy on-site software revisions and upgrades.