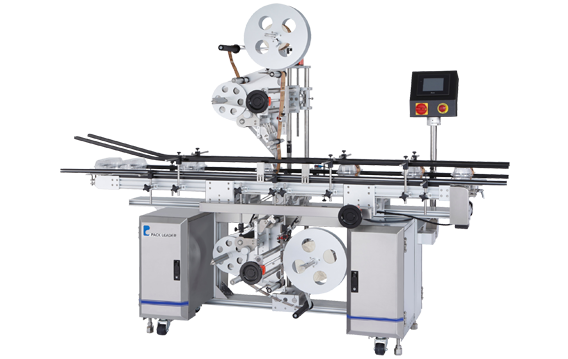

Product Description

Model Number:PRO-225D

The PRO-225D Clamshell Labeling Machine is capable of applying top and bottom labeling for clamshell packages and is also capable of applying C shaped and L shaped labeling. The PRO-225D’s unique wipe-in design allows label to secure on the container with superb accuracy. It also includes the optional feature to do a full wrap or under-tuck tamper evident seal.

The conveyor system incorporates twin belts for transferring, aligning, and spacing clamshell packaging to the labeling station for maximum efficiency. To ensure a perfect labeling accuracy, products will be pre-aligned before going into the labeling station. While a special wipe system provides a nice finish on the tamper evident seal, a mechanism will drive the label deeper into the dent of the container for an even more secure and excellent labeling result. Optional features for the machine includes hot stamp printer, thermal transfer, and the Print and Apply system.

Frame Assembly

- Made from S304 stainless steel and hardened anodized aluminum, maintenance of the labeler is easy and efficient.

Control Interface

- Control system of labeler utilizes a large touch screen panel, certified by CE and UL regulations for efficient and effective monitoring of the labeling process.

- Control box and external connection of labeler pass CE and UL safety regulations with IP65 level to ensure control system longevity and stability.

Applicator Assembly

- Labeling process controlled by Panasonic micro process controller PLC, ensuring a fast and steady performance.

- Label dispensing is driven by stepper motor to ensure labeling accuracy, efficiency, and speed while being low on energy consumption. (For high speed demands, the servo motor can be selected)

- Utilizes famous branded fiber optics and infrared sensors for precise detection and signal triggering without interference.

- Standard label applicator width both 180mm and 250ml optional. Applicator is ready for future hot foil printer assembly attachment.

- The labeler is easily adjustable with the included hand wheel assembly. It is efficient and effective for various label positioning, maximizing production output.

Labeler Component Advantages

- Maintenance is easy and efficient.

- Delicate VFD controller ensure speed stability and +/-0.5% inaccuracy rate.

- Guide rail portion is made with high quality aluminum covered with hard-wearing industrial plastic to ensure accurate labeling and product protection, keeping the customer’s product attractive and in perfect condition.

- Labeler base is made of stainless steel to ensure full anti-rusting. This design ensures the machine and production space hygiene are maintained which is normally neglected by other manufacturers.

- Wheels keep the machine portable, convenient when shifting to different production lines. This supportive mobile strength increases the value of your investment.

| Supply Voltage |

220/110 VAC 50/60Hz 1Phase |

| Power Consumption |

880VA |

| Dispensing Speed |

40m/min max. |

| Conveyor Speed |

40m/min max. |

| Applicator Height |

180mm / 200mm / 250mm |

| Label Size |

170mm x 300mm max. |

| Conveyor Width |

160mm |

| Spool Diameter |

76mm |

| Dimension |

1835mm (L) x 800mm(W) x 1360mm(H) |

—Specifications are subject to change without prior notice—-